Vent Drill Bit Selection Guide for Maintenance of Tire Molds

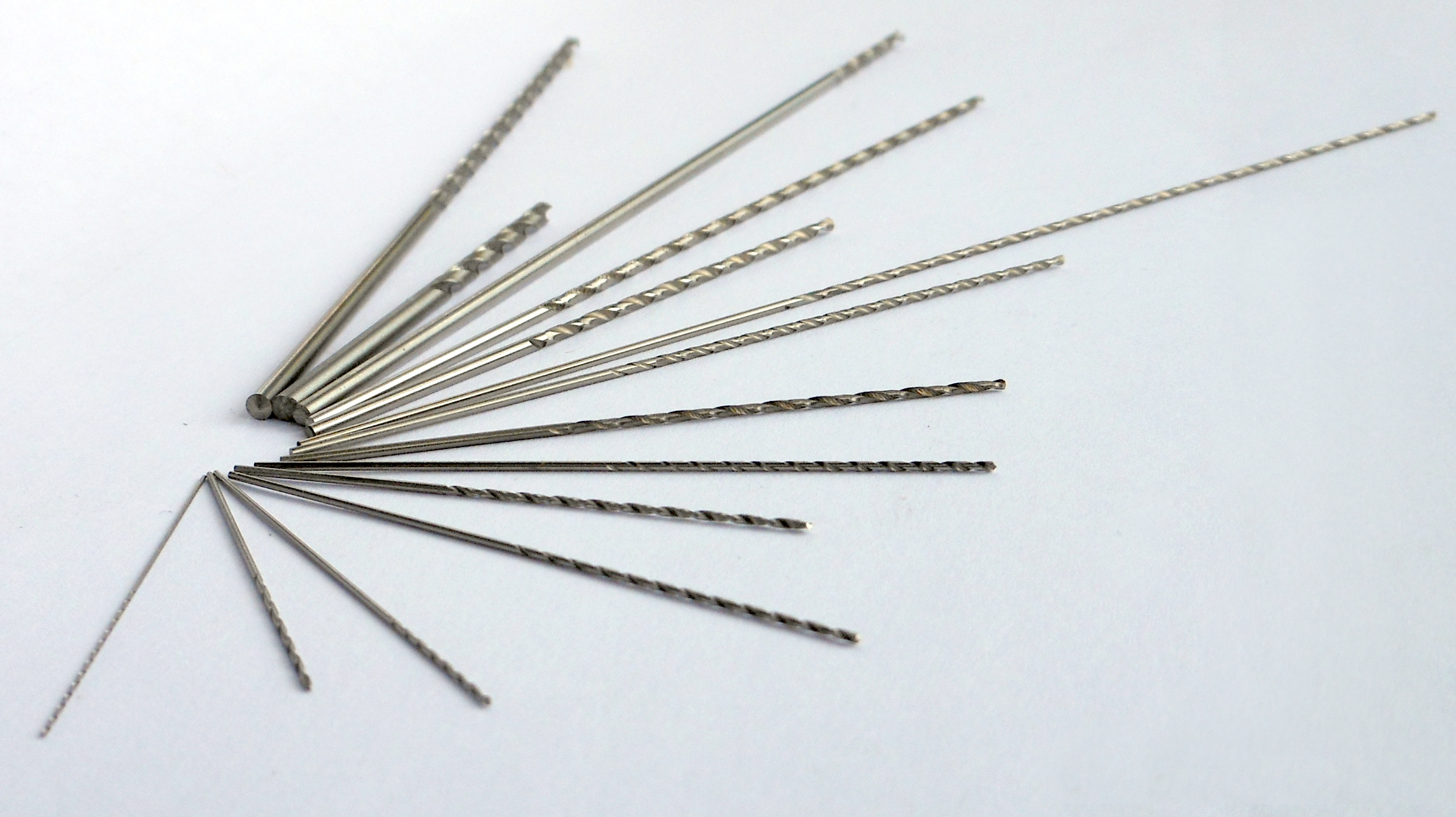

Ensuring the lifespan and performance of molds for tire production requires proper vent hole drilling. This guide assists you in selecting the right vent drill bit for optimal maintenance.

Vent holes are critical for tire mold performance. They allow trapped air to escape during the injection process, preventing air pockets and defects in vulcanized rubber.

Proper vent drilling prevents material build-up and premature wear on the tire mold. By ensuring efficient air flow, it facilitates easier release and reduces the risk of defects in the tire.

Available measures: Metric

- MATERIAL : Hss/Co, Hss, M2

- DIAMETER (mm) : 0.18, 0.21, 0.4, 0.45, 0.5, 0.53, 0.55, 0.57, 0.57, 0.61, 0.63, 0.65, 0.7, 0.72, 0.73, 0.75, 0.79, 0.8, 0.9, 0.92, 1.0, 1.1, 1.2, 1.25, 1.3, 1.4, 1.5, 1.61, 1.6, 1.7, 1.9, 2.0, 2.1, 2.2, 2.3, 2.4, 2.5, 2.6, 2.7, 2.8, 3.0, 3.1, 3.2, 3.3, 3.5, 4.0,

- HELIX (Flute) in mm : 10, 15, 20, 25, 30, 35, 40, 50, 60, 80, 100, 120, 140, 150, 180, 200

- LENGTH in mm : 30, 35, 40, 42, 45, 50, 55, 60, 65, 70, 80, 90, 100, 120, 150, 180, 200, 250

- GEOMETRY Quick, Standard, Parabolic

Wire Gauge-Fractional

- MATERIAL : Hss/Co, Hss, M2

- DIAMETER : #80, #79, 1/64, #78, #77, #76, #75, #74, #73, #72, #71, #70, #69, #68, 1/32, #67, #66, #65, #64, #63, #62, #61, #60, #59, #58, #57, #56, 3/64, #55, #54, #53, 1/16, #52, #51, #50, #49, #48, 5/64, #47, #46, #45,

- HELIX (Flute) in inches : 1', 1.1', 2', 2.5', 3', 4', 5'

- LENGTH in inches : 1', 1.1', 2', 2.5', 3', 4', 5', 6', 8

- GEOMETRY Quick, Standard, Parabolic